Table of Contents

Finished Size : 600~3000 mesh

Processing Ability : 3 – 45t/h

Max feeding Size : 10 mm

MQQ : 1 Set

Price: 129999-599999 $

Range Of Application: Calcium Carbonate 、Limestone 、Kaolin、Gypsum 、Bentonite、Dolomite…

| Main Configuration and Production | |||

| Model | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 5 | 7 | 7 |

| Power of classifier(Kw) | 5X15 | 7X15 | 7X(15~18.5) |

| Main unit power (Kw) | 250 | 315 | 355 |

| Blower power(Kw) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=34% output(t/h) |

11-14 | 13-17 | 15-19 |

| Less than 2μm=46% output(t/h) |

7-8 | 9-10 | 11-12 |

| Less than 2μm=60% output(t/h) |

3-4 | / | / |

| Material: based on calcite Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

CLUM Series Ultrafine Vertical Roller Mill is a new grinding equipment produced by shanghai Clirik, it can be used in stone powder process with many types.

Ultrafine Vertical Roller Mill are suitable for huge capacity producing, widely used in grinding non-flammable and non-explosive materials under 7(the Moh’s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

CLUM Series Ultrafine Vertical Roller Mill Use the special anti-wear alloy materials for grinding roller and plate liner. Long service time for wear parts, low maintenance. The grinding curves of the roller shell and liner plate are uniquely designed, easy to form the stable material bed, low vibration, high product efficient. It is 20% higher than other equivalent vertical mill in capacity, saving 40% powder consumption compared with ball mill.

CLUM Series Ultrafine Vertical Roller Mill Adopting the multi-rotor classifier, the final particles size for D97 5-45 micron are attainable. Equipped with the PLC frequency converter control system, the CLUM mill can produce 2 micron (20-70%) powder and adjust powder selection patterns according to client’ different requirements. It has greatly increased the final powder added value and application areas due to the advantages of narrow particle size distribution, unit form particles shape and controllable 2 micron content.

CLUM Series Ultrafine Vertical Roller Mill pressure being applied to the grinding roller auto-controlled by the PLC/DSC enables the accurate control of grinding pressure and highly efficiency without manual operation. The roller shell and grinding disc liner plate gap is dual protected by electronic and mechanical caging devices to avoid the heavy vibration and impact. The reducer box and lubricating system are equipped with multiple inspection and cycle with double pumps. The sufficient lubrication and cooling of the bearings for the grinding roller is ensured therefore no excess of lubricating oil in the bearing chamber and no leakage could occur.

CLUM Series Ultrafine Vertical Roller Mill roller and grinding disc do not touch each other directly, there does not have the metal impact noise in low vibration. Compared with ball mill the running noise is 20-25db lower which would not hurt human’s health. Hermetic seal ensures that the system operates under negative pressure. The final powder is conveyed to the final product silo without dust leakage. The environment is clean, meeting the national environmental protection requirements.

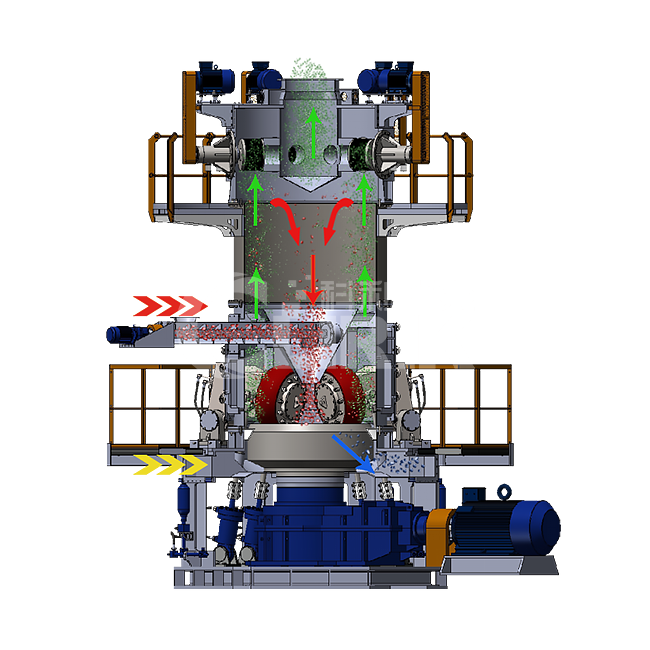

CLUM series ultrafine vertical roller mill mainly consists of the motor,reduction gear,grinding rollers,grinding plate,pressure-applying device,classifier,mill body.oil station ,and electrical system.

Ultrafine Vertical Roller Mills grinding plate is rotated by the main motor via the reduction gear. Meanwhile ,high pressure air enters the mill interior via inlet. Materials then fall onto the center of the grinding plate in rotation by the screw conveyor feeder.Due to the centrifugal force,the materials evenly move from the center of the grinding plate towards its fringe. While passing across the track in the grinding plate,large blocks of materials are crushed and grinded directly by the grinding roller.the fine particles form the material bed ,owing to squeezing ,where the inter-particle crushing takes place until grind to the fine powder.

Ultrafine Vertical Roller Mills fine powder continue to move towards the fringe of the grinding plate until they are taken away by strong air flow at the air ring.While the materials along with the air flow pass through the separator located above the grinding plate,the coarse particles return to the grinding plate for re-pulverization due to the action of the rotor blade,the fine particles along with the air flow leave the mill interior and are collected and discharged as finished powder product by the powder collector.

1. In the process of using CLUM series ultrafine vertical roller mill, a special person should be responsible for it, and the post responsibility system and operation specification should be established. The operator must be familiar with the performance, operation requirements and operation procedures of the machine. New staff must pass technical training, to meet the requirements of the post operation.

2. The lubrication work of ultra-fine CLUM series vertical mill must be done well. The addition of too much or too little lubricant will affect the mill. The selection of lubricants in winter and summer should be correct, and the cleaning work of the mill must be paid attention to. Impurities will pollute the lubricant and affect its lubrication effect. It is best to thoroughly clean and add new lubricants regularly according to the working intensity.

3. Always check the backblowing air pressure of the filter bag filter, so as to avoid blockage of the filter bag. The decline of the fan current will affect the output of the equipment. Check the dust collector regularly. If the filter bag is damaged, it should be replaced in time to avoid dust leakage and pollution.

4. Always check the parts and components, and tighten them in time when they are loose to avoid accidents; if the wearing parts such as roller, ring, plate and shaft pin are found to be seriously worn, the wearing parts should be replaced at the same time to ensure normal production; the muffler should be cleaned regularly to avoid excessive resistance and affecting the system air volume.

5. When using CLUM series ultrafine vertical roller mill for production, pay attention to avoid outdoor production. Sun and rain can cause varying degrees of damage to the mill. If water enters the body, the effect is even worse.

6. The working time of the mill should be planned in detail. Machines and people alike should try to avoid overwork. Overwork operation is not only low production efficiency, but also great damage to the machine.

When the maintenance of the mill is done well, the failure frequency of the ultra-fine mill can be reduced appropriately and effectively. Timely maintenance for occasional failures can get twice the result with half the effort. In fact, the maintenance of the machine is also a kind of maintenance, because no matter how high quality mill equipment can not stand arbitrary operation, the quality is decided by the manufacturer, the maintenance is in their own hands, if the combination of the two will be better.