Today we Shanghai Clirik Machine Co., Ltd. to explain to you “HGM Series micro powder grinding mill in the processing of limestone has what advantages? “I hope it will be helpful to our customers.

HGM Series Micro Powder Grinding Mill

Finished Size: 150-2500 mesh

Processing Ability: 1-45 t/h

Max Feeding Size: 10-25 mm

MQQ : 1 Set

Price: 59999- 159999 $

Range Of Application: Limestone ,Calcium Carbonate ,Kaolin,Gypsum ,Bentonite,Dolomite…

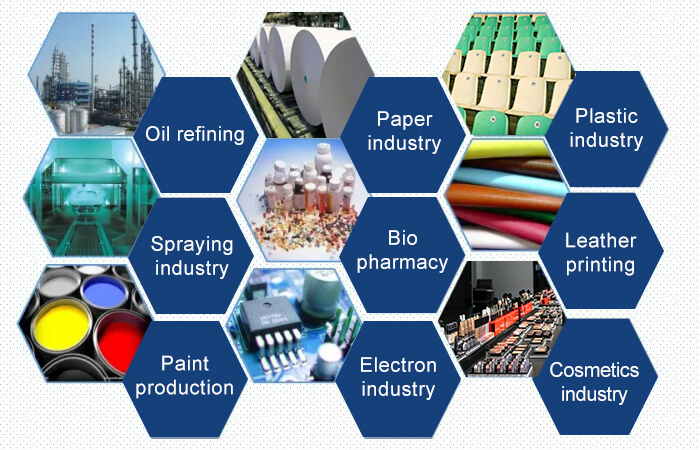

As an important building material, limestone has a long mining history. With the change of time, the continuous progress of science and technology and the development of nanotechnology, the application of limestone will be further widened. In the modern industry, there is a manufacturer of cement, lime, calcium carbide limestone main raw material. It is an indispensable flux limestone in the metallurgical industry. high-quality limestone flour mill equipment used after crushing, grading, separation, can be widely used in papermaking, rubber, paint, paint, pharmaceutical, cosmetic, feed, sealing, bonding, polishing and other products.

The wide use of limestone also promotes the gradual increase in the demand for lime powder in the construction industry, so that the price of lime powder is increasingly growing. The major mill manufacturers are also their own talent, competing to transform the grinding equipment, in order to obtain the favor of lime powder manufacturers.

Shanghai Clirik machinery Co., Ltd. as a well-known mill manufacturer in Shanghai, naturally can not lag behind. We have been engaged in the grinding industry for many years and have rich experience in ore research. A group of mining machinery industry elites gathered here, forming a professional R & D team, the introduction, absorption, digestion of domestic and foreign advanced technology and processes. Independent research and development of the production of a suitable for grinding various materials of HGM series micro powder grinding mill, these grinding mills have achieved remarkable results in practice, for customers to strive for the greatest benefits, has been the consistent favor of customers at home and abroad.

With the same final particle size of the finished product, the capacity of ultrafine powder grinding mill is twice as much as jet mill,mixing grinder and ball mill,and energy consumption decreased 30%.

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size , the lifecycle of spare parts is about one year,which is 2-3 times longer than impact mill or turbo mill. Furthermore,the lifetime can reach 2-5 years for grinding calcite carbonate. The lifecycle of spare parts is variable for the material’s hardness.

As no rolling bearings or screws in gridning cavity,there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

The final fineness of the gridning materials can be adjusted between 200 meshes and 2500 mesh (74-5micron).

The application of pulse bag filter and muffler greatly alleviates dust pollution and nosise.

Let the material feed into te machine evenly,adjust the main speed to fit for grinded material,the fineness more stable. So as to increase the capacity and efficiency, reduce the powder consumption.