Today, Shanghai Clirik welcomed two customers from Haiti to inspect YGM series limestone Raymond mill, according to the customer’s general description, the demand is to have more Raymond mill processing limestone, foreign trade Department manager Zhu soon recommended our company’s 1900A Raymond mill for customers.

This limestone Raymond mill, whether from the discharge fineness or production efficiency, can well meet the production needs of users, detailed for customers to introduce the working principle and performance characteristics of Raymond mill.

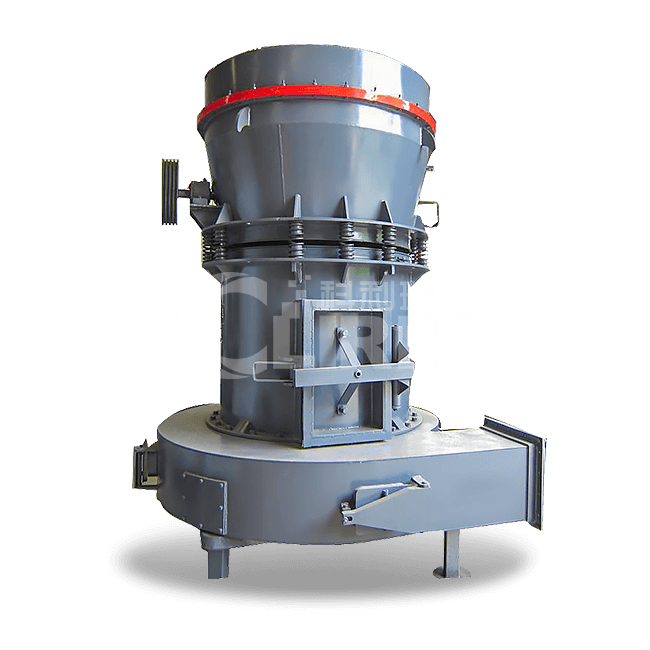

Manager Zhu first led customers to our mill exhibition hall to show customers the YGM series limestone Raymond mill, according to the actual Raymond mill in the exhibition hall again introduced its structure and use precautions to customers. The customer was very satisfied with Manager Zhu’s work enthusiasm and the mill he recommended to them.

In the whole process of communication and introduction, the customer expressed great appreciation for the service of our technical staff, and was very interested in our company’s equipment, and said that after discussing with their company, they will reach a cooperative relationship with us as soon as possible.

Raymond mill is a commonly used grinding equipment for various non-metallic minerals. Limestone Raymond mill is a specific type of Raymond mill that is used for processing limestone, a sedimentary rock primarily composed of calcium carbonate. Here’s an introduction to the key aspects of the Limestone Raymond mill:

Components

The main components of the Limestone Raymond mill include the grinding roller, grinding ring, analyzer, blower, finished product cyclone separator, plumbing installation, motor, and other components. Each component plays a crucial role in the overall functioning of the mill

Working Principle

Limestone Raymond mill operates on the principle of grinding and crushing. The material is fed into the machine from the feeding hopper on the side of the machine, and the grinding roller device suspended on the main stand rotates around the vertical axis. Meanwhile, the centrifugal force produced by the rotation of the grinding roller pushes the grinding ring to grind the material.

Application Range

Limestone Raymond mill is widely used in the processing of various non-metallic minerals with Moh’s hardness less than 7 and humidity less than 6%. It is suitable for grinding and processing materials such as limestone, calcite, marble, talc, dolomite, barite, gypsum, and other mineral powders.

Advantages

1. High Efficiency: The grinding efficiency of the Limestone Raymond mill is high, and the finished product has a uniform particle size.

2. Wide Application: It can process a variety of non-metallic minerals, making it versatile for different industries.

3. Low Maintenance: The design of the mill reduces the frequency of maintenance, ensuring a longer service life.

4. Particle Size Adjustment:The particle size of the finished product can be adjusted within the range of 80-325 mesh. Users can adjust the fineness according to their specific requirements.

5.Environmental Protection: The Limestone Raymond mill is equipped with a dust removal system to minimize dust pollution during the milling process, making it environmentally friendly.

Clirik Machinery Co., Ltd. is a professional manufacturer of grinding mill machines, crushers, and other mining equipment. based in China. They have been in the industry for many years and have gained a solid reputation for their high-quality products.

Product Range

Clirik specializes in the production of various types of grinding mills, and among them, the Limestone Raymond mill is one of their key products. Their range of grinding mills caters to different industries and applications, including mining, metallurgy, chemical engineering, and construction.

Quality Assurance

Clirik is known for its commitment to quality assurance. They implement strict quality control measures in the manufacturing process to ensure that their equipment meets industry standards and customer expectations.

Innovation and Technology

Reputable manufacturers often invest in research and development to incorporate the latest technologies into their products. Clirik is likely to focus on innovation to enhance the performance and efficiency of their grinding mills, including the Limestone Raymond mill.

Global Presence

Clirik products are distributed and used globally. They may have established a presence in various countries and regions, serving a diverse customer base.

Customer Support and Service

A reliable manufacturer typically provides excellent customer support and after-sales service. This includes technical support, spare parts availability, and assistance with any issues that customers may encounter during the operation of their equipment.

Environmental Responsibility

In line with industry trends, Clirik may incorporate environmentally friendly features into their equipment, such as dust collection systems and energy-efficient designs.