Table of Contents

Finished Size : 50-325 mesh

Power: 18.5-132 kw

Processing Ability: 1-30t/h

Max feeding Size: 20 mm

MQQ : 1 Set

Price: 9999-99999 $

Range of application: Calcium Carbonate 、Limestone 、Kaolin、Gypsum 、Bentonite、Dolomite…

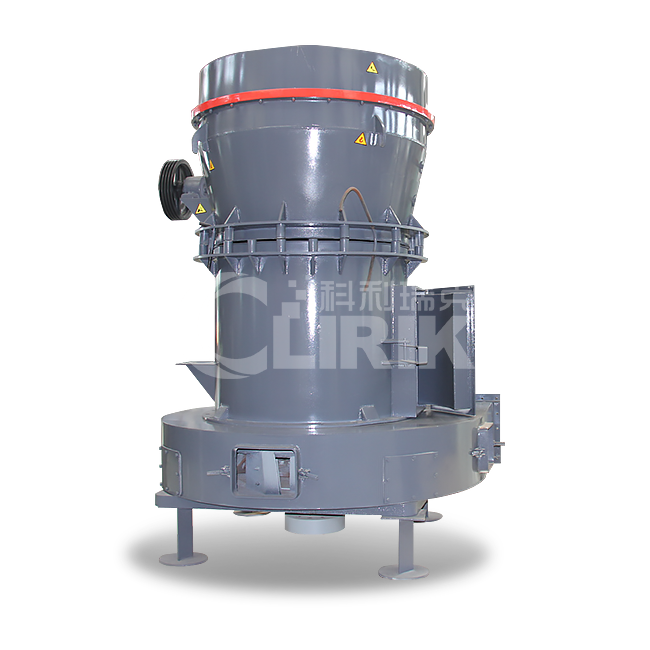

YGM series high pressure suspension grinding mill is suitable for processing various non-lammable and non-explosive mineral materials with Moh’s hardness less than 6 and humidity less than 6%.

It is widely used in the fields of metallurgy, construction, chemical industry, mining, highway construction etc, The granularity of the finished powder size can be adjusted between 50 and 325 meshes (315-45 micron). Examples of processing materials include quartz, feldspar, barite, calcite carbonate, limestone, talc, ceramic, iron ore, carborundum, bauxite, rock phosphate, coal and other materials, total about 400 kinds of materials.

| Model | Roller | Ring | Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*1050 |

1.High Efficiency

Under the same finished final size and the same motor power, the capacity of the machineis twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

2.Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization,the lifetime can reach 2-5 years for grinding calcite.

3.High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

4.High fineness, flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D97≤5μm.

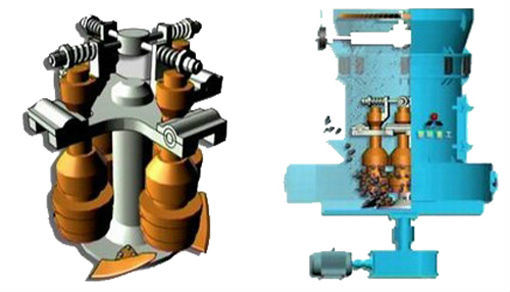

YGM series high pressure suspension grinding mill is mainly composed of main unit, analyzer, fan, dischargeing cyclone separator, powder cyclone separator and air duct. Among them, the main unit consists of frame, blow shell, shovel, grinding roller and grinding ring.

1. The lump material will be conveyed into the storage bin by the bucket elevator after it is crushed into the required particle size by the jaw crusher.

2. Then electro vibrating feeder will uniformly transfer the material into the grinding chamber of the host machine.

3. The material is up thrown and fed into the space between the grinding roller and grinding ring in the process of synchronous rotation of the shovel and the grinding roller, and forms a cushion material layer.

4. The material on this layer is grinded between the grinding roller and the grinding ring. Thus, the purpose of powder production is achieved.

5. The grinded powder will be carried by the airflow of the fan into the analyzer for classification.

6. The powder with the qualified fineness will enter the large cyclone collector, together with the airflow through the pipes, for classification, and then, will be discharged by the discharging device, as the finished product.

7. The airflow is sucked into the air blower through the air return pipe on the upper part of the large cyclone collector.

8. The unqualified powder will be thrown to the external wall by the airflow and separated from the airflow.

9. The coarse powder will fall into the grinding chamber for regrinding due to its own gravity.

10. The whole airflow system is closed and cyclic, and it flows under the positive and negative pressure circularly.