Table of Contents

Limestone has excellent properties such as thermal conductivity, firmness, water absorption, impermeability, sound insulation, polishing, good cementation and processability, which can be used directly or deeply processed. Therefore, limestone is an important industrial raw material widely used in metallurgy, building materials, chemical industry, light industry, construction, agriculture and other special industrial sectors.

Limestone (limestone) is referred to as Limestone, carbonate rock with calcite as the main component. Sometimes contain dolomite, clay minerals and detrital minerals, gray, gray, gray black, yellow, light red, brown red and other colors, hardness is generally not large, and dilute hydrochloric acid has a violent chemical reaction. According to genetic classification, it belongs to sedimentary rocks.

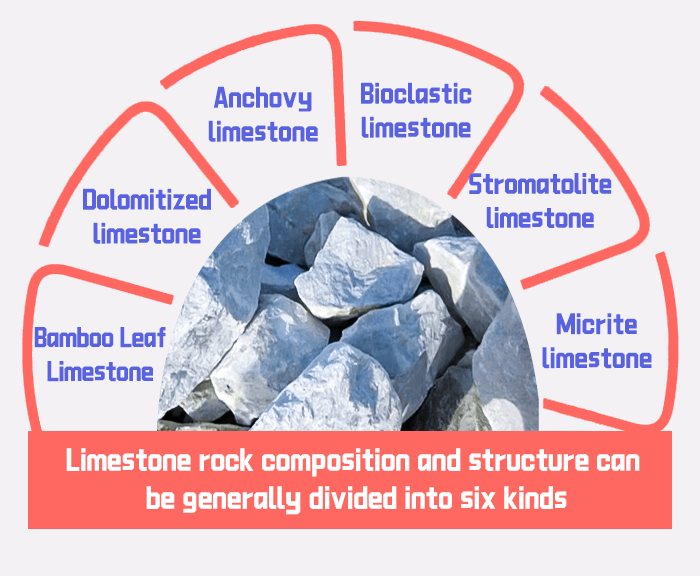

Limestone is mainly formed in shallow sea environments. Limestone can be divided into granular limestone (water transport, depositional formation), biological skeleton limestone and chemical and biochemical limestone according to its origin. According to the structure, it can be subdivided into bamboo-leaf limestone, oolitic limestone, leopard-skin limestone, and agglomerate limestone.

The structure of limestone is more complex, including clastic structure and grain structure. The clastic structure is composed of grains, micritic matrix and sparry cements. Particles are also called particles, mainly including endoclasts, bioclasts and oolitic particles. Micritic matrix is a plaster composed of fine particles or crystals of calcium carbonate with particle point less than 0.05 mm. Sparry cements are chemical precipitates filled in the pores between rock particles and calcite crystal particles with diameter greater than 0.01 mm. Grain structure is the crystal particles precipitated by chemical and biochemical processes.

The mineral composition of limestone is dominated by calcite, accompanied by carbonate minerals such as dolomite and magnesite, and some other impurities. Among them, magnesium is white limestone and magnesite, silicon oxide is free quartz, stone pulp and opal distributed in the rock, alumina with oxidation silicification to synthesize aluminum silicate (clay, feldspar, mica); the iron compounds are carbonate (magnesite), pyrite (pyrite), free oxide (magnetite, hematite) and hydroxide (hydrogoethite). In addition, there are glauconite, certain types of limestone and coal, organics such as asphalt and sulfates such as gypsum and anhydrite, as well as phosphorus and calcium compounds, alkali metal compounds and strontium, barium, manganese, titanium and fluorine, but in very low concentrations.

Limestone has good processability, polishing and cementation properties. It is insoluble in water and soluble in saturated sulfuric acid. It can react with various strong acids to form corresponding calcium salts and emit CO2 at the same time. Limestone calcination to 900℃ above (generally 1000~1300℃) decomposition into lime (CaO), release CO2. Hydrated lime [Ca(OH)2] is formed immediately when the quicklime is deliquescent in water. The hydrated lime can be adjusted after being dissolved in water and is easy to harden in air.

Limestone can be broken by jaw crusher or cone crusher for a first stage, and then by impact crusher or hammer crusher for a second stage, and finally by micro powder grinding mill or ultrafine vertical grinding mill for powder.

Quicklime can be used as bordeaux liquid, lime and sulfur mixture and other pesticides. Slaked lime can change the acidity and alkalinity of soil, improve the internal composition of soil and supplement the calcium in soil. The lime slurry can then be used to paint the tree trunk, which can protect the tree.

Limestone is the main raw material for making cement. In addition, limestone can be used to build the exterior walls and floors of houses.

Glass is made of limestone, quartz sand, soda ash and other materials, which can be obtained after high temperature smelting.

In industrial production, limestone is also a solvent for iron making and gangue removal. Quicklime is used here, which can be used as slagging material to filter out harmful substances such as sulfur and phosphorus.

Limestone after chemical processing, can become calcium chloride, calcium nitrate, calcium sulfite and other calcium salts.

Hydrated lime is used in industry as a hard water softener because it can temporarily remove the hardness of water.

According to incomplete statistics, the total consumption of limestone and construction stone, quicklime, metallurgical solvent and ultrafine calcium carbonate paper and pen in cement production is 1:3.

HGM series micro powder grinding mill is a kind of high efficiency, low consumption and environmental protection superfine powder processing equipment designed by the technical department of our company after many innovations and tests. Fineness between 150-2500 mesh can be adjusted arbitrarily.

CLUM series ultrafine vertical powder grinding mill is a comprehensive large-scale grinding equipment designed by Clirik, which integrates grinding, grading, drying, transportation, secondary powder selection, finished product packaging and other six functions. It has the characteristics of centralized process flow, low operation cost, stable product quality, convenient maintenance and green environmental protection. Fineness between 325-3000 mesh can be adjusted arbitrarily, 2 micron content can do about 70%.