Table of Contents

Diatomite Powder Ultrafine Grinding Mill

Modle : HGM Series

Finished Size: 325-2500 mesh

Processing Ability: 1-45 t/h

Max Feeding Size: 10-25 mm

MQQ : 1 Set

Price: 59999- 159999 $

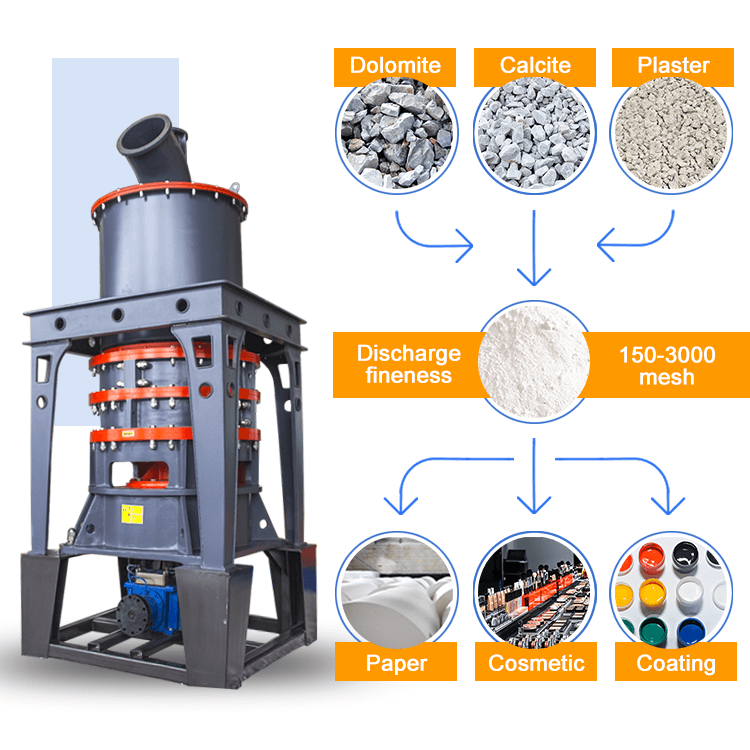

Range Of Application: Diatomite,Calcium Carbonate ,Talc ,Kaolin,Gypsum ,Limestone,Kaolin,Bentonite,Dolomite…

Diatomite powder ultrafine grinding mill (also called diatomite micro powder grinding mill, ultrafine roller mill,pulverizer mill,ultra-fine roller grinding mill) is mainly suitable for medium and low hardness, Ultra-fine powder processing of non-flammable and explosive brittle materials with Mohs hardness ≤6, Such as diatomite,calcite, chalk, limestone, carbon black, kaolin, talc, mica, bentonite, magnesite, illite and pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alum stone, graphite, fluorite, phosphate rock, potassium ore, pumice, such as more than 100 kinds of materials, fine powder product granularity between 325-2500 mesh adjusted, The output can reach 0.4-45 tons per hour.

Diatomite powder ultrafine grinding mill structure composition

The main part of the diatomite powder ultrafine grinding mill is composed of the main engine, reducer, analysis engine, fan, bypass powder collector, maintenance platform and electric control cabinet. The auxiliary part is composed of a jaw crusher, bucket elevator, electromagnetic vibration feeder, storage bin, etc.

Diatomite powder ultrafine grinding mill working process

When diatomite powder ultrafine grinding mill works, the main motor drives the spindle and the turntable to rotate through the reducer, and the roller pin on the edge of the turntable drives dozens of rollers to roll in the raceway of the grinding ring.

The bulk material is broken into small particles by the hammer crusher and then sent to the storage bin by the Bucket Elevator, and then through the vibration feeder and the inclined feed pipe, the material is evenly sent to the upper part of the rotary plate on the bulk plate.

The material disperses to the surrounding circle under the action of centrifugal force, and falls into the raceway of the grinding ring by the ring roller impact, rolling, grinding, after three layers of ring road processing into powder, high-pressure fan through the suction effect of the external air into the machine, and the pulverized material into the separator.

The rotating impeller in the powder separator makes the coarse material fall back and regrind, and the fine powder meets the requirements is entered into the cyclone powder collector with the airflow and discharged by the discharge valve at the lower part of the finished product, while the airflow with a small amount of fine dust is discharged through the fan and muffler after the pulse dust collector.

Diatomite powder ultrafine grinding mill Precautions for operation

1. Check the bearing temperature frequently. If the temperature is too high, check whether the lubrication and transmission parts are normal and whether the rolling distance is too tight. Find out the reason in time, take corresponding measures, if the situation is serious, stop the inspection.

2. Often check the tightness of the belt. If the belt is too loose will reduce the transmission efficiency and affect the grinding effect, too tight is easy to cause bearing heat, increase power consumption, reduce the service life of the belt.

3. Various transmission parts must be fastened and reliable. Special tools should be used for disassembly or installation.

4. Don’t forget to check the pneumatic components, plastic grinder after startup, often should check the pneumatic components in the gas circuit, gas path and joint leakage or damage, at the same time to check the gas supply pressure is in line with the requirements, the use of synchronous belt, also want to check if discover too tight, too loose, jitter, wandering, severe wear, etc., should be timely adjust, repair or replacement.

5. The oil storage capacity of the oil atomizer in the air source triplet should be checked regularly. It is necessary to add 20# spindle oil to avoid blockage of the small hole in the pipeline.

1. High efficiency and energy saving.

When the fineness of the finished product and the power of the motor are the same, the output of diatomite powder ultrafine grinding mill is more than twice as high as that of airflow Mill, stirring Mill and ball Mill.

2. Long service life of wearing parts

Diatomite powder ultrafine grinding mill roller, Grinding ring is forged by special material, so that the utilization degree is greatly improved. Generally can reach more than one year, processing calcium carbonate, calcite, the service life can reach 2-5 years.

3. High safety and reliability.

Because there is no rolling bearing and no screw in the grinding cavity, there is no problem that the bearing and its seal are easy to be damaged, and there is no problem that the screw is easy to loosen and damage the machine.

4. Environmental protection and cleaning.

Diatomite powder ultrafine grinding mill uses pulse dust catcher to capture dust, muffler to reduce noise, has the characteristics of environmental protection and clean.

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Clirik is a trusted partner. We can provide you with the following services.

Full service:

Raw material testing-program design-equipment manufacturing-installation-commissioning-technical training-up to standard and production-after-sales service.

Factory direct supply:

More than 30 years of experience in R&D and manufacturing, and 120+ countries and regions coverage. The source manufacturer has no middleman, higher cost performance, and excellent quality, ingenuity.

Ingenuity:

Clirik provides solutions for calcite grinding/crushing and screening, tailor-made solutions for you.

Automatic equipment production, the pipe wall is thicker and resistant to compression and deformation, environmentally friendly materials are harmless, and support customization.

Because there are 5 different kinds of diatomite powder ultrafine grinding mill, so our diatomite powder ultrafine grinding roller mill unit has different prices, I need to ask you for some details for sending you the more suitable quotation:

1.Which kind of material are you going to grind?

(Diatomite,dolomite; calcite; quartz; basalt; barite; limestone; feldspar; gravel; bentonite; gypsum; granite; coal; slag; pebble; others)

2.What’s the production capacity you want? How many tons or cubic meters per hour?

( > 100 TPH > 50 TPH > 30 TPH > 10 TH > 1 TPH < 1 TPH)

3.What’s the granularity of the final products you need?

(in milimeter, micron or mesh)

4. What’s the max input size of the material?

(In inch, centimeter or millimeter)

If you would like more details, please contact our customer service.