Table of Contents

Diatomite Powder Ultrafine Vertical Roller Mill

Modle : CLUM Series

Finished Size: 400-3000 mesh

Processing Ability: 3 – 45t/h

Max Feeding Size: 10 mm

MQQ : 1 Set

Price: 129999- 599999 $

Range Of Application: Diatomite, Calcium Carbonate, Talc, Kaolin, Gypsum, Kaolin, Bentonite, Carbon black, Calcite, Limestone…

Diatomite powder ultrafine vertical roller mill has high grinding efficiency, low energy consumption, uniform particle shape, narrow particle size distribution, good fluidity, and strong product adaptability. It is an ideal non-metallic ores powder making equipment.

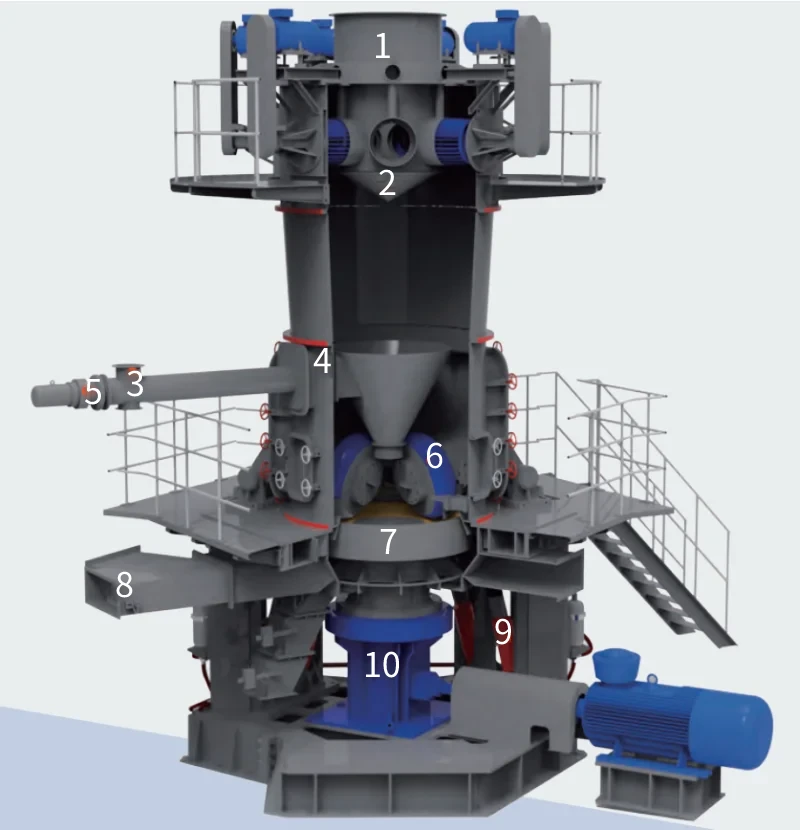

The main engine of diatomite powder ultrafine vertical roller mill is mainly composed of motor, reducer, machine body, grinding roller device, grinding disc device, pressurizing device, powder separator, lubricating station, hydraulic station, etc.

1 Finished product discharge port.

2 Powder concentrator.

3 Inlet.

4 middle body.

5 Screw conveyor.

6 Grinding roller assembly.

7 Grinding disc assembly.

8 Air inlet.

9 Working hydraulic cylinder.

10 Motor and reducer.

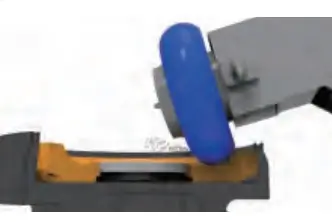

Grinding rollers and discs are made of highly wear-resistant materials, with long service life and low maintenance costs.

The grinding zone between the grinding roller and the grinding disc adopts a special grinding curve design to ensure the stable operation of the host and effective grinding.

The pressure of the grinding roller adopts a hydraulic tension rod with adjustable elastic coefficient to ensure the continuous pressure of the grinding roller on the material.

he grinding roller and the grinding disc are not in contact, and the mechanical limit device is adopted to avoid damage, impact and vibration.

The multi-rotor high-efficiency cage powder separator has high powder separation efficiency and is easy to adjust and control, and can quickly produce a variety of finished products.

The diatomite powder ultrafine vertical roller mill grinding disc is driven by a motor through the reducer.

The materials fall into the center of the grinding disc through the elevator, screw conveyor, star-shaped feeding valve, and feeding screw, and move to the edge of the grinding disc under the action of centrifugal force. When passing through the grinding zone between the grinding roller and the grinding disc, it is crushed by the pressure of the grinding roller and the shearing force between the grinding disc and the grinding roller.

The pulverized material continues to move to the edge of the grinding disc until it is brought into the multi-rotor powder concentrator at high speed by the airflow from the high-pressure fan on the edge of the grinding disc for classification.

The powder that does not meet the requirements falls into the grinding disc and re-grinds. The powder that meets the requirements is collected by the airflow into the dust collector, and sent to the finished product warehouse by the lifting system or the pneumatic conveying system.

Diatomite powder ultrafine vertical roller mill are suitable for huge capacity producing, widely used in grinding non- flammable and non-explosive materials under 6 (the Moh’s hardness), such as Bamboo, gypsum, calcium carbonate, quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Diatomite powder ultrafine vertical grinding mill can be widely applied in the industries of chemicals, metallurgy, non-metallic ores etc. In particular, it is outstanding in processing white superfine non-metallic ore powders, providing superior quality fillers and additives for paper making, coating materials, plastics, rubber, PVC, printing ink etc.

1. Low Operation Cost.

Use the special anti-wear alloy materials for grinding roller and plate liner. Long service time for wear parts, low maintenance. The grinding curves of the roller shell and liner plate are uniquely designed, easy to form the stable material bed, low vibration, high product efficient. It is 20% higher than other equivalent vertical mill in capacity, saving 40% powder consumption compared with ball mill.

2.High Additional Value

Adopting the multi-rotor classifier, the final particles size for D97 5-45 micron are attainable. Equipped with the PLC frequency converter control system, the diatomite powder ultrafine vertical grinding mill can produce 2 micron (20-70%) powder and adjust powder selection patterns according to client’ different requirements. It has greatly increased the final powder added value and application areas due to the advantages of narrow particle size distribution, unit form particles shape and controllable 2 micron content.

3. Safe And Reliable.

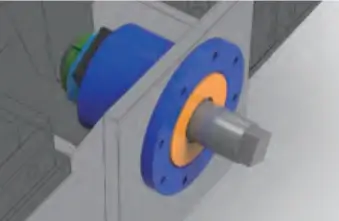

The pressure being applied to the grinding roller auto-controlled by the PLC/DSC enables the accurate control of grinding pressure and highly efficient without manual operation; the roller shell and grinding disc liner plate gap is dual protected by electronic and mechanical caging devices to avoid the heavy vibration and impact. The reducer box and lubricating system are equipped with multiple inspection and cycle with double pumps.

The sufficient lubrication and cooling of the bearings for the grinding roller is ensured therefore no excess of lubricating oil in the bearing chamber and no leakage could occur. equipped with multiple intelligent protection devices, the diatomite powder ultrafine vertical roller mill main unit can realize the continuous operation with stable, safe and high-efficient performance rather than stop running.

4. Environmental Friendly.

Product Advantage of diatomite powder ultrafine vertical roller mill and grinding disc do not touch each other directly, there does not have the metal impact noise in low vibration, compared with ball mill the running noise is 20-25 db lower which would not hurt human’s health. Hermetic seal ensures that the system operates under negative pressure.The final powder is conveyed to the final product silo without dust leakage. The environment is clean, meeting the national environmental protection requirements.

| Main Configuration and Production | |||

| Model | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 5 | 7 | 7 |

| Power of classifier(Kw) | 5X15 | 7X15 | 7X(15~18.5) |

| Main unit power (Kw) | 250 | 315 | 355 |

| Blower power(Kw) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=34% output(t/h) |

11-14 | 13-17 | 15-19 |

| Less than 2μm=46% output(t/h) |

7-8 | 9-10 | 11-12 |

| Less than 2μm=60% output(t/h) |

3-4 | / | / |

| Material: based on calcite Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

– Diatomite powder ultrafine production line

Diatomite powder ultrafine vertical roller mill have a large capacity, stable operation, low wear, long life, environmental protection and energy saving, simple operation, intelligent control system, easy maintenance, and the fineness can be freely adjusted between 400-3000 meshes.

The fineness of the diatomite powder produced can reach 3000 mesh. The finished powder has high whiteness, good powder ball shape, high 2um fine powder content, and more fine powder content. Diatomite is a high-end powder wear resistance, heat resistance, water absorption and many other excellent performance, especially suitable for filler, filter aid, catalytic carrier, adsorbent, environmental building materials and so on.

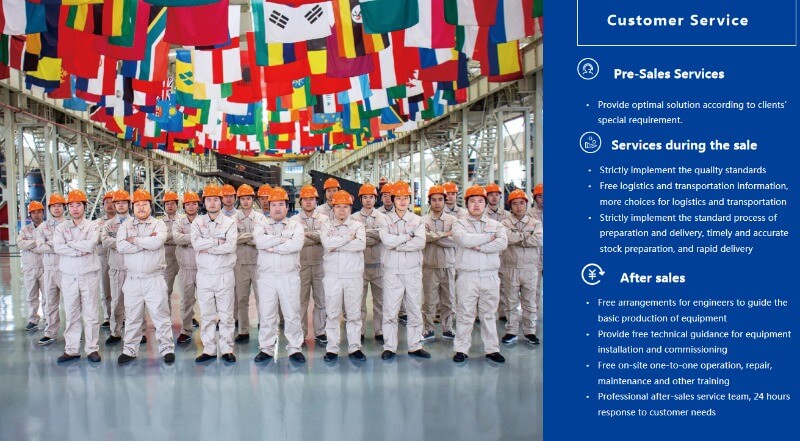

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai China as a professional enterprise, which specializes in research, manufacture and sales of all kinds of mining equipment. We have established a whole production chain. We still insist on communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always be on the industry front.

Clirik is a trusted partner, we can provide you with the following services:

Full service:

Raw material testing-program design-equipment manufacturing-installation-commissioning-technical training-up to standard and production-after-sales service.

Factory direct supply :

More than 30 years of experience in R&D and manufacturing, and 120+ countries and regions coverage. The source manufacturer has no middleman, higher cost performance, and excellent quality, ingenuity.

Ingenuity :

Clirik provides solutions for calcite grinding/crushing and screening, tailor-made solutions for you.

Automatic equipment production, the pipe wall is thicker and resistant to compression and deformation, environmentally friendly materials are harmless, and support customization.

① The diatomite powder ultrafine vertical roller mill integrates crushing, grinding, grading, drying, and conveying into one.

② The system configuration is scientific and reasonable, the equipment layout is compact, the floor space is small, and the sealing performance is superior.

③ The oxygen content in the mill is low, the explosion suppression performance is superior, and the grinding process is safe and controllable.

④ The pulse dust collector can achieve 99.99% dust collection, creating a safe and dust-free environment-friendly workshop.

The mill structure, scraper, hydraulic system, material, and pressure difference will all affect the grinding efficiency of the vertical mill.

The hardness, composition, viscosity, moisture, and particle size of the grinding material will all affect the output, so the appropriate grinding machine should be selected according to the nature of the grinding material.

When grinding, the feed should be uniform and stable, and the classification efficiency should be controlled reasonably. Regular inspection and maintenance of wearing parts, hydraulic systems, etc.

● The diatomite powder ultrafine vertical roller mill integrates crushing, grinding, grading, drying, and conveying.

● Advanced control system.

● The material is wear-resistant and has a long service life.

● High production capacity and low power consumption.

● Environmental protection.

● The finished product has good quality, high whiteness, fine particle size, good particle sphere shape, and narrow particle size distribution.

CE, ISO9001

Factory sells directly

30 years experience, professional

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union