Table of Contents

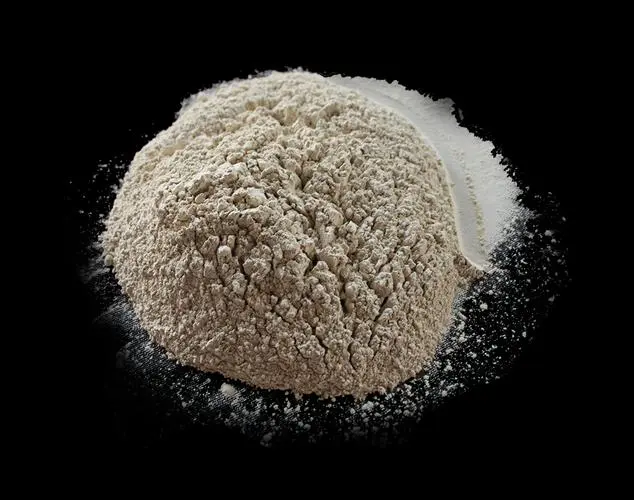

Bauxite powder refers to finely ground bauxite ore that has been processed into a fine powder form. It is typically produced by crushing and grinding raw bauxite ore into a fine particle size to facilitate its use in various applications.

Production: Bauxite powder is produced through the process of grinding raw bauxite ore into a fine powder form. This process involves crushing the bauxite ore into smaller particles and then grinding it into a fine powder using grinding mills or pulverizers.

Particle Size: The particle size of bauxite powder can vary depending on the specific requirements of its intended use. It can range from coarse particles to very fine powders, typically with particle sizes ranging from a few micrometers to several tens of micrometers.

Composition: Bauxite powder retains the chemical composition of the original bauxite ore, primarily consisting of aluminum hydroxide minerals (such as gibbsite, boehmite, and diaspore) along with various impurities such as iron oxide, silica, and titania.

Uses: Bauxite powder has various industrial applications due to its aluminum content and other properties. Some common uses include:

Bauxite is a naturally occurring, heterogeneous material composed primarily of aluminum hydroxide minerals, along with various impurities such as iron oxide, silica, and titania. It is the primary ore of aluminum and is typically found in tropical or subtropical regions.

Composition: Bauxite primarily consists of aluminum hydroxide minerals, including gibbsite, boehmite, and diaspore. These minerals are usually mixed with varying amounts of impurities such as iron oxide (Fe2O3), silica (SiO2), and titania (TiO2).

Appearance: Bauxite can vary in color from reddish-brown to white, depending on the composition and impurities present. It often has a pisolitic or nodular structure due to the concentration of aluminum hydroxide minerals.

Formation: Bauxite forms through weathering and chemical decomposition of aluminum-rich rocks under tropical or subtropical conditions. The process typically involves the leaching of aluminum from parent rocks and subsequent concentration in residual soils or sedimentary deposits.

Mining and Extraction: Bauxite is mined through open-pit or strip mining methods. After extraction, the ore undergoes beneficiation to remove impurities and improve its aluminum content. The primary method of aluminum extraction from bauxite is the Bayer process, which involves digestion of the ore with caustic soda (sodium hydroxide) at elevated temperatures to dissolve the aluminum hydroxide minerals. The resulting solution is then processed to extract pure aluminum hydroxide, which can be further refined into aluminum metal through electrolysis.

Uses: The primary use of bauxite is as a raw material for the production of aluminum metal. Aluminum is widely used in various industries, including aerospace, automotive, construction, packaging, and electronics, due to its lightweight, corrosion resistance, and excellent conductivity properties. Additionally, bauxite-derived alumina (aluminum oxide) is used in the manufacture of abrasives, refractories, ceramics, and other industrial applications.

Processing aluminum ore into powder involves several steps to extract the aluminum metal from its ore, bauxite. Here’s a general overview of the process:

1. Mining and Crushing: Bauxite ore is typically mined in open-pit mines and then transported to a processing plant. At the processing plant, the ore is crushed into smaller pieces using crushers or hammer mills to facilitate further processing.

2. Grinding and Grinding Mills: The crushed bauxite ore is then ground into a fine powder using grinding mills. Various types of mills can be used, including ball mills, vertical roller mills, jet mills, and stirred media mills, depending on the desired particle size and other specific requirements.

3. Digestion and Bayer Process: After grinding, the bauxite powder is mixed with a hot, concentrated solution of sodium hydroxide (NaOH) in a process called digestion. This step is part of the Bayer process, which extracts alumina (aluminum oxide) from the bauxite ore. The sodium hydroxide dissolves the alumina from the bauxite, leaving behind impurities such as iron oxides and silica.

4. Clarification and Precipitation: The resulting solution, called sodium aluminate, is then clarified to remove any remaining solid impurities. The clarified solution is cooled and seeded with aluminum hydroxide crystals to initiate precipitation. This precipitation process causes the aluminum hydroxide to separate from the solution.

5. Calcination: The aluminum hydroxide precipitate is then heated in a kiln or rotary furnace in a process called calcination. This converts the aluminum hydroxide into alumina (aluminum oxide) by driving off the water molecules.

6. Aluminum Smelting: The alumina is then smelted in a smelting pot or electrolytic cell to produce molten aluminum metal. In the smelting process, an electric current is passed through the alumina, causing the aluminum ions to migrate to the cathode, where they are reduced to form liquid aluminum metal. This liquid aluminum is then cast into various shapes or further processed to produce aluminum products.

7. Recycling: Aluminum can also be recycled from scrap metal, which involves melting down the aluminum scrap and reprocessing it into new aluminum products. Recycling aluminum is an energy-efficient process that helps conserve natural resources and reduce environmental impact.

Processing aluminum ore into powder involves a series of mechanical, chemical, and thermal processes to extract aluminum metal from its ore and convert it into usable products. Each step in the process requires careful control and optimization to ensure efficient production and high-quality aluminum products.