Table of Contents

Petroleum coke powder ultrafine grinding machine refers to the equipment used to grind petroleum coke into fine powder. Petroleum coke is a carbonaceous solid that comes from refinery cokers or other cracking processes. It is commonly used as a fuel in industrial applications or as a raw material for the production of electrodes, anodes and various carbon-based products.

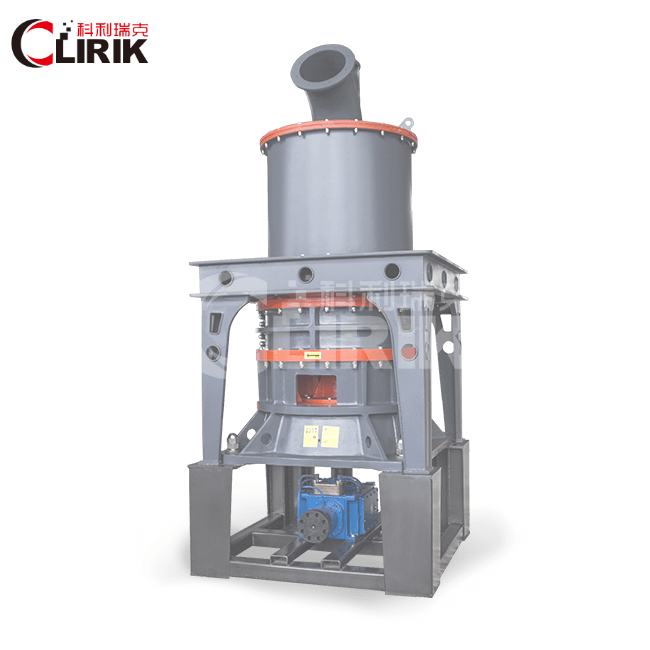

There are various types of mills that can be used to grind petroleum coke into powder, including Raymond mills, vertical roller mills, ball mills, etc. Today I will mainly introduce Clirik’s HGM series petroleum coke powder ultrafine grinding machine.

Petroleum coke powder ultrafine grinding machine: HGM series superfine petroleum coke pulverizer is a large-scale grinding equipment integrating crushing, grinding, grading and conveying. It has the characteristics of high crushing efficiency, low power consumption, large feed particle size, and convenient adjustment of product fineness. Ultrafine petroleum coke powder ultrafine grinding machine is often used in petroleum coke grinding process.

Finished Size: 150-2500 mesh

Processing Ability: 1-45 t/h

Max Feeding Size: 10-25 mm

MQQ : 1 Set

Price: 59999- 159999 $

Range Of Application: Petroleum coke , Calcium carbonate, Limestone, Kaolin, Gypsum, Bentonite, Dolomite…

HGM Series Petroleum Coke Superfine Grinding Machine, also known as HGM Petroleum Coke Grinding Machine, is a high-efficiency and energy-saving grinding equipment specially designed for processing petroleum coke into superfine powder. It is a pulverizer commonly used in petroleum coke powder production line.

Following are some main features and characteristics of Petroleum Coke Powder Ultrafine Grinding Machine:

Petroleum coke ultra-fine grinding machine adopts advanced grinding technology and optimized design, which greatly improves the grinding efficiency. It can grind petroleum coke into fine powder with high fineness.

Petroleum coke powder ultrafine mill can produce ultrafine powder with a particle size range of 300-2500 mesh. This allows precise control of the fineness of the final product according to specific requirements.

The petroleum coke pulverizer is equipped with a powerful motor and an advanced grinding system, which reduces energy consumption and ensures efficient grinding. It also features a dust collection system to minimize dust emissions and create a cleaner working environment.

HGM series grinding machine adopts multi-stage grinding and classification process, which improves the grinding efficiency and ensures the consistent and uniform product quality.

In addition to petroleum coke, petroleum coke powder ultra-fine grinding machine can also be used to grind various non-flammable and explosive materials with a hardness below 7 and a water content below 6%, such as calcite, limestone, dolomite, kaolin, bentonite, talc, Mica, magnesite, illite, pyrophyllite, vermiculite, etc.

When choosing a Petroleum coke powder ultrafine grinding machine, factors such as production capacity, required fineness, energy consumption, and equipment price need to be considered. It is very important to choose the right grinding machine according to your specific requirement s.

Our company has various models of HGM series petroleum coke powder ultrafine grinding machine for you to choose from.

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

It should be noted that when using a petroleum coke powder ultrafine grinding machine, proper operation and maintenance should be followed to ensure the best performance and service life of the equipment. In addition, safety measures should be taken to deal with the potential flammability of petroleum coke particles.

When using a petroleum coke powder ultrafine grinding machine, it is very important to ensure that the following safety measures are followed:

Before using the ultrafine mill, the operator should understand the equipment’s operation manual and safety precautions in detail. Ensure operators have the necessary knowledge and skills to safely operate and maintain the mill.

Operate in accordance with the operating procedures provided by the equipment manufacturer, and follow relevant safety procedures. Make sure to use each operation switch and control device correctly to avoid accidents caused by misoperation.

Petroleum coke is a combustible dust, so steps need to be taken to control dust. Make sure that the ultra-fine pulverizer is equipped with an effective dust collection system, and that it is cleaned and maintained regularly to prevent the accumulation and accumulation of dust that can cause fire or explosion.

Regular equipment inspection and maintenance is the key to ensure the normal operation of the ultrafine mill and prolong its service life. Check the electrical connection, lubrication system, wear parts, etc. of the equipment, and repair or replace them in time.

Follow the rated operating parameters and load range of the equipment, and avoid overload operation to prevent equipment damage or accidents.

Operators should wear appropriate personal protective equipment, such as protective glasses, dust masks, fire-resistant gloves, etc., to protect their own safety.

In a word, safety measures such as following the correct operating procedures, strengthening equipment maintenance, controlling dust and wearing personal protective equipment can minimize the occurrence of accidents and ensure work safety when using petroleum coke powder ultrafine grinder.

Shanghai Clirik Machinery Co., Ltd. is a well-known enterprise specializing in the production of petroleum coke powder ultra-fine grinding machines and other grinding equipment. The following is a brief introduction to Shanghai Keliruike Machinery Co., Ltd.

Firmenname:Shanghai Cliric Machinery Co., Ltd.

Location: No. 19, Fuqing Road, Heqing Town, Pudong, Shanghai, China

Overview: Shanghai Cliric Machinery Co., Ltd. is a professional manufacturer and supplier of pulverizers, crushers and other mining equipment. The company places great emphasis on research and development, innovation and customer satisfaction. They are known for providing high quality grinding machines and solutions for various industries.

Product Range: Shanghai Cliric Machinery Co., Ltd. provides a variety of grinding equipment, including but not limited to:

1. Raymond mill: The company produces various types of Raymond mills, which are suitable for grinding different materials, including petroleum coke.

2. Vertical Roller Mills: They offer vertical roller mills designed for efficient grinding of a wide variety of materials including petroleum coke. These grinders are characterized by high grinding efficiency and energy saving.

3. Ball Mills: Clirik also manufactures ball mills that can be used to grind petroleum coke and other minerals.

4. Ultrafine Mills: They offer ultrafine mills that can produce fine and ultrafine powders with high precision and fineness.

These are just a few examples of the grinding equipment offered by Shanghai Clearrick Machinery Co., Ltd. We manufacture a wide range of mine processing products which can be customized to meet specific customer requirements.

Quality and Service:

Shanghai Clirik Machinery Co., Ltd. is known for its commitment to quality and customer satisfaction. They adhere to strict quality control measures during the manufacturing process, ensuring that their grinding machines comply with international standards. The company also provides customers with excellent after-sales service, technical support and assistance.

Innovation and Research:

Shanghai Clirik Machinery Co., Ltd. pays great attention to innovation and research. They continuously invest in research and development activities to enhance the performance, efficiency and technological advancement of their products. This commitment to innovation enables them to provide cutting-edge grinding solutions to their customers.