Table of Contents

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service. This article mainly introduces three kinds of commonly used crushers produced by our company.

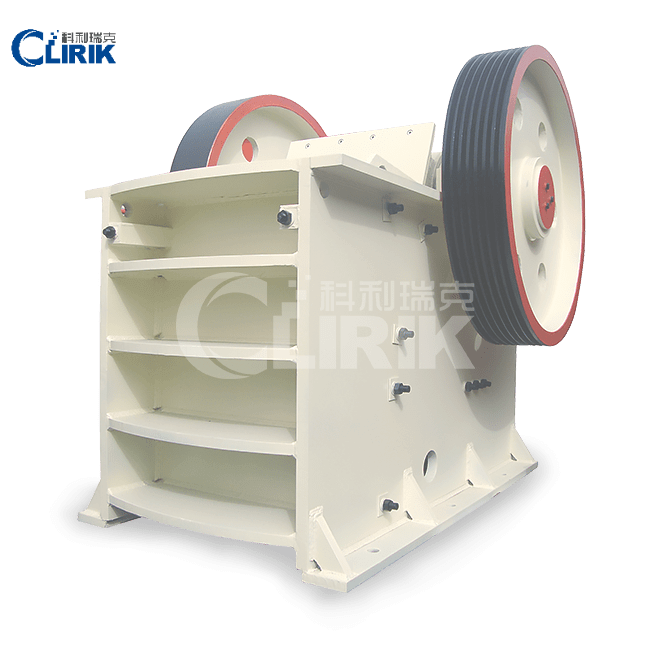

Jaw crushers break materials by extrusion.

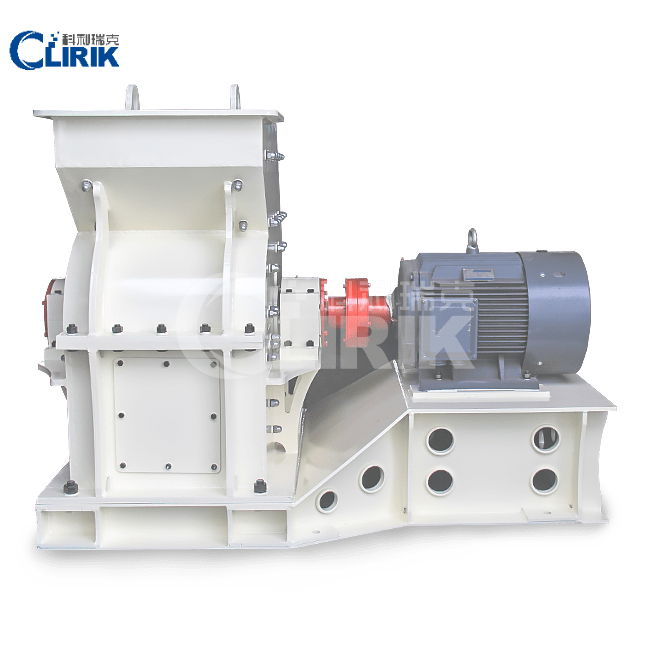

Hammer crusher is mainly by impact to break the material

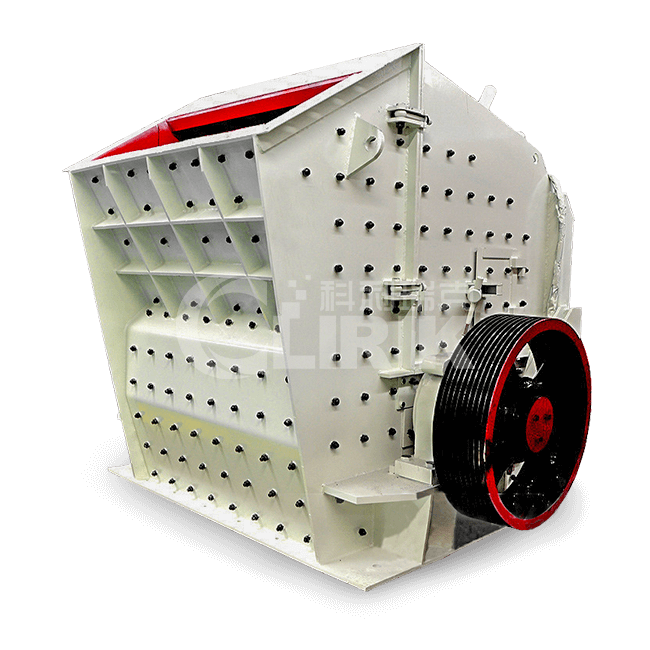

Impact crusher is the use of impact energy to break materials.

PEX Jaw Crusher

Jaw Crusher

Output Size: 25-105 mm

Feed size.: <250 mm

Capacity: 1-90 t/h

Use Range : Calcite、Calcium Carbonate、Dolomite、Gypsum、Carbon Black、Gypsum、Kaolin、 Marble …

Application : Mining、Chemiscal、 Pigment、 Plastic、Transport and many other different areas.

JEX Jaw Crusher working mode for flexural extrusion type,It works like this: An electric motor drives the belt and pulley, and the jaw moves up and down through an eccentric shaft,When the moving jaw rises, the Angle between the toggle plate and the moving jaw becomes larger, which pushes the moving jaw plate to the fixed jaw plate. At the same time, the material is crushed or split to achieve the purpose of crushing.When the moving jaw goes down, the Angle between the toggle plate and the moving jaw becomes smaller. The moving jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring. At this time, the broken material is discharged from the lower mouth of the crushing chamber. With the continuous rotation of the motor, the motor jaw is broken to crush and discharge materials in a periodic motion, so as to achieve mass production

PFW Impact Crusher

Finished Size : 0-200 mm

Processing Ability : 90-450t/h

Max feeding Size : 800 mm

Range Of Application: Calcium Carbonate 、Limestone 、Kaolin、Gypsum 、Bentonite、Dolomite…

PFW Impact Crusher working principle: is the use of impact energy to break the material. When the material into the plate hammer function area, to make the flat hammer in overpressure by high-speed impact being constantly being broken into the installation of the counter device on the top of the rotor, and then back to the board from the back plate hammer function area to be punished, material from big to small in the crushing cavity repeated broken, until the material being broken to the required size, lower discharge by machine.

PC Series Hammer Crusher

Hammer Crusher

Output Size: 5-20 mm

Feed size.: <350 mm

Capacity: 5-30 t/h

Use Range : Calcite、Calcium Carbonate、Dolomite、Gypsum、Carbon Black、Gypsum、Kaolin、 Marble …

Application : Mining、Chemiscal、 Pigment、 Plastic、Transport and many other different areas.

PC Series Hammer Crusher working principle: hammer crusher is mainly by impact to break the material.Crushing process is that the material into the crusher, subjected to high speed rotating hammer impact and broken, broken material obtained from hammer kinetic energy, from high speed toward the body, screen, meanwhile material impact each other, have been broken many times, the clearance of the material is less than the bar, from the eduction in clearance, individual large material, on the bar again by the hammer head The impact, grinding, extrusion and crushing, the material is extruded from the gap by the hammer. To obtain the desired granularity of the product.

— SHANGHAI CLIRIK MACHINERY CO., LTD

Our company already has a complete modern production line, equipped with intelligent and standardized testing and control laboratories, and has a professional team integrating R&D, production, sales and service.

Pre-sale service:

1.Clirik provides a variety of mining equipment for you to choose from.

2.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3. Clirik customizes the logo and color of the grinding equipment according to your company image.

4. Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and use videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.