Table of Contents

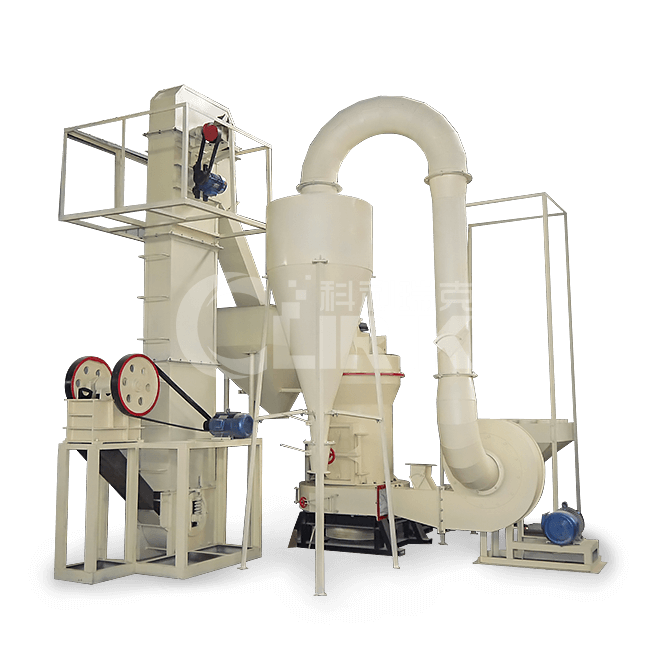

Modle : CLUM Series

Finished Size: 400-3000 mesh

Processing Ability: 3 – 45t/h

Max Feeding Size: 10 mm

MQQ : 1 Set

Price: 129999- 599999 $

Range Of Application: Fluorite, Calcium Carbonate, Talc, Kaolin, Gypsum, Kaolin, Bentonite, Dolomite…

The fluorite powder ultrafine vertical roller mill is mainly used in the production of fluorite powder. The Ultra-fine vertical mill integrates crushing, drying, grinding and conveying, which is especially suitable for large-scale production of ultra-fine powder processing of non-metallic minerals.

Fluorite, also known as fluorspar, is the main source of fluorine in industry and one of the 20 important non-metallic mineral raw materials in the world. It is widely used in metallurgy, aluminum smelting, glass, ceramics, cement, chemical industry.

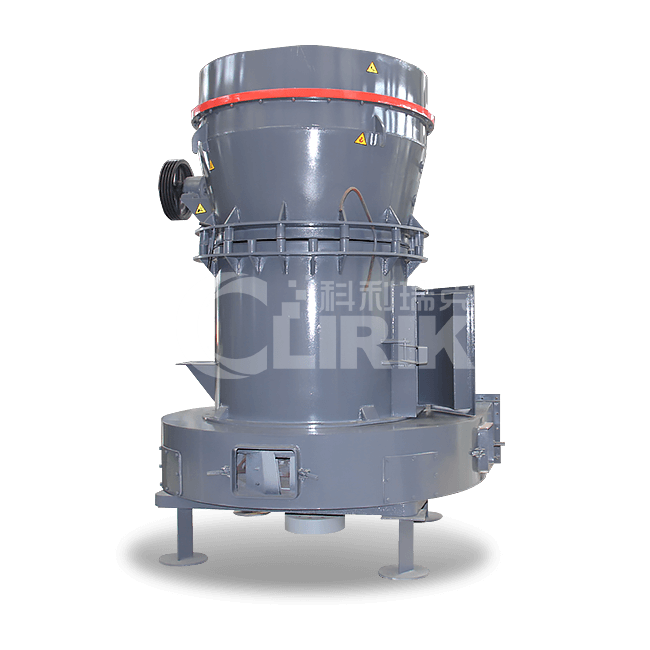

Structure of fluorite powder ultrafine vertical roller mill:

1. Grinding disc: including guide ring, wind ring, retaining ring, lining plate, disc body, scraper and lifting device, etc.

2. Grinding roller: The roller sleeve is an easy to wear part, which requires sufficient toughness and good wear resistance.

3. Powder separators can be divided into three categories: static, dynamic and high-efficiency combined powder separators:

4. Pressure device: hydraulic device, accumulator.

5. Monitoring device: rocker monitoring, vibration monitoring.

6. Transmission device: electric motor, reducer.

7. Water spray system: reduce the temperature and stabilize the material layer.

8. Coarse powder external circulation system: elevator.

1. Fluorite powder ultrafine vertical roller mill plate is rotated by the main motor via the reduction gear.

2. Meanwhile, high pressure air enters the mill interior via inlet.

3. Materials then fall onto the center of the grinding plate in rotation by the screw conveyor feeder.

4. Due to the centrifugal force, the materials evenly move from the center of the grinding plate towards its fringe.

5. While passing across the track in the grinding plate, large blocks of materials are crushed and grinded directly by the grinding roller.

6. The fine particles form the material bed, owing to squeezing, where the inter-particle crushing takes place until grind to the fine powder.

7. Fluorite powder ultrafine vertical grinding mill fine powder continue to move towards the fringe of the grinding plate until they are taken away by strong air flow at the air ring.

8. While the materials along with the air flow pass through the separator located above the grinding plate.

9. The coarse particles return to the grinding plate for re-pulverization due to the action of the rotor blade.

10. The fine particles along with the air flow leave the mill interior and are collected and discharged as finished powder product by the powder collector.

| Main Configuration and Production | |||

| Model | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 5 | 7 | 7 |

| Power of classifier(Kw) | 5X15 | 7X15 | 7X(15~18.5) |

| Main unit power (Kw) | 250 | 315 | 355 |

| Blower power(Kw) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=34% output(t/h) |

11-14 | 13-17 | 15-19 |

| Less than 2μm=46% output(t/h) |

7-8 | 9-10 | 11-12 |

| Less than 2μm=60% output(t/h) |

3-4 | / | / |

| Material: based on calcite Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

The fluorite powder ultrafine vertical roller mill system has simple process flow, compact layout, and small building area. It covers an area of about 70% of the ball mill system, and the building space is about 60% of the ball mill system.

It can be arranged in the open air, which directly reduces the investment cost of the enterprise. And the vertical grinding mill itself has a separator, so there is no need to add a powder separator and lifting equipment. The dust-containing gas from the mill can be directly collected by a bag filter or an electric dust collector.

The fluorite powder vertical grinding mill grinds materials by the principle of material layer grinding, with low energy consumption. The power consumption of the grinding system is 20% to 30% lower than that of the ball mill, and the energy saving effect is more obvious as the moisture of the raw material increases. Compared with the ball mill system, the energy consumption of the vertical mill system can be reduced by 30% to 40%

The fluorite powder vertical grinding mill does not have the metal impact sound of the steel balls colliding with each other and the liner in the ball mill, so the noise is low, which is 20-25dB lower than that of the ball mill. In addition, the vertical mill adopts a fully enclosed system, the system works under negative pressure, no dust, and the environment is clean.

The fluorite ultrafine powder vertical grinding mill adopts hot air to transport materials, and when grinding materials with high moisture content, the inlet air temperature can be controlled to make the product reach the required final moisture. It can be dried in the vertical mill grind materials with a moisture content of up to 15% to 20%.

Equipped with an automatic control system, it can realize remote control and is easy to operate; by checking and repairing the oil cylinder and turning the boom, the roller sleeve and liner can be replaced conveniently and quickly, and the loss of the enterprise can be reduced.

The chemical composition of the product is stable, and the particle size is uniform, which is good for calcination. the residence time of the material in the fluorite powder vertical mill is only 2~3min, while it takes 15~20min in the ball mill. Therefore, the chemical composition and fineness of vertical mill products can be quickly determined and corrected.

Because there is no direct metal contact between the grinding roller and the grinding disc in the operation of the fluorite powder ultrafine vertical roller mill, the wear is small, and the metal consumption per unit product is generally 5-10g/t.

Fluorite is widely used in metallurgy, aluminum smelting, glass, ceramics, cement, chemical industry.

Pure, colorless and transparent fluorite can be used as optical materials, beautiful color fluorite can also be used as gem stone and arts and crafts carving raw materials.

Fluorite is the basic raw material of fluorine chemical industry, its products are widely used in aerospace, aviation, refrigeration, medicine, pesticides, anti-corrosion, fire fighting, electronics, electric power, machinery and atomic energy and other fields.

We can provide you with CLUM series fluorite powder ultrafine vertical roller mill can also provide you with fluorite powder ultrafine grinding mill,YGM series fluorite powder high pressure suspension grinding mill, LXMC series fluorite powder ultra fine wet stirring mill, CLRM series fluorite powder enhanced roller grinding mill, PC series European coarse powder grinding mill.

1. Why do you choose the fluorite powder ultrafine vertical roller mill?

Fluorite powder ultrafine vertical roller mill produces higher fineness and better quality powder than traditional mills. Applicable to a more high-end market, better earnings.

2. Why do you choose Shanghai Clirik Machine Co., LTD?

Because we not only have high quality ultrafine mill equipment, but also excellent service, we can provide customers with site survey, scheme design, on-site installation, technical personnel training and other services.

3. What modes of transportation do you have?

We have land transportation, sea transportation, air transportation and other modes of transportation. You buy each item we will verify the packaging, to ensure that you can receive the goods for installation and production.

4. Which payment methods do you favor?

L/C, Western Union, D/P, D/A, T/T, MoneyGram, negotiable